- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

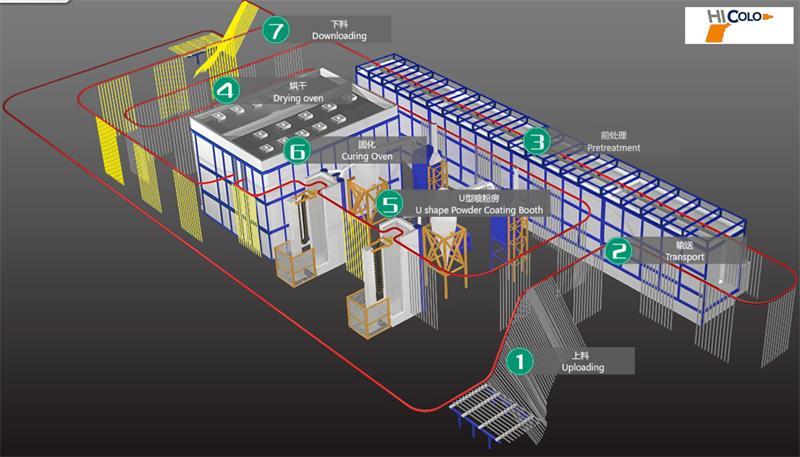

Vertical Automatic powder coating plant for aluminium profile

High production vertical powder coating system for the aluminium profile

vertical powder coating system provides high production capacity with the ability to economically powder coat extrusions in small runs with multiplepowder color changes each shift. The system is designed to automatically powder coatextrusions in lengths up to 8m

2,

Energy Saving Pretreatment Washer

A key component of the vertical powder coating system is the pretreatment washer system. COLO design uses an innovative spraying style washer to provide high performance pretreatment of the aluminum extrusionsThe spraying washer design eliminates the use of thousands of spray nozzles typically found inside the washer tunnel of a vertical coating line. The system uses low maintenance trays to direct the flow of each pretreatment stage down over the top of the extrusions similar to a waterfall. Using the system reduces the pretreatment chemical costs and saves water.

3,fast color powder spray booth with recovery system

Powder recovery and reclaim is accomplished using high efficiency cyclone technology allowing reclaim of high volume colors and spray to waste capabilities for short color run requirements. The high efficiency cyclone system can recover approximately 98% of the powder overspray and return it to the powder feed system for reuse.

4,Indirectly Heated Powder Cure Oven

After application of the powder coatings, the aluminum extrusions proceed to an indirectly heated convection oven for a complete cure of the powder coatings. The natural gas fired ovens are very energy efficient in design and provide the optimum environment to cure the powder coatings. Indirectly heating the powder cure oven eliminates the concerns about possible contaminants from the burner and helps provide excellent control over the temperature profile within the oven.

5,Automatic download the part

COLO could offer the different powder coating solution according to your parts and requirements.

Welcome to contact us as follow:

- Phone

- *Title

- *Content

- Phone

- *Title

- *Content