- Powder Coating Gun

- Powder Coating Booth

- Powder Coating Oven

- automatic powder coating gun and equipment

- Reciprocator for pwoder coating gun

- powder coating line

- Powder feed center

- Powder Hopper

- Tribo powder spray gun

- Electrostatic Liquid Spray Guns

- Sandblasting Machine

- Parker Ionics Replacement Part

- powder coating testing meter

- Powder Coating Line Spare Part

- Powder Coatings

- NEW products

- Powder Coating Gun Machine on Sale

- KCI powder coating gun spare part

- PG1 / PG2A / GM02 / GA02 / GM03 / GA03 Powder coating gun spare part

- PEM C4 / X1 Powder Spray gun parts

- Encore / Prodigy / Vantage / Sure Coat / Versa-Spray / 100 Plus Feed Pumps spray gun parts

- Sames / Eurotec Powder coating gun parts

- COLO powder coating gun parts

- bo'x feed

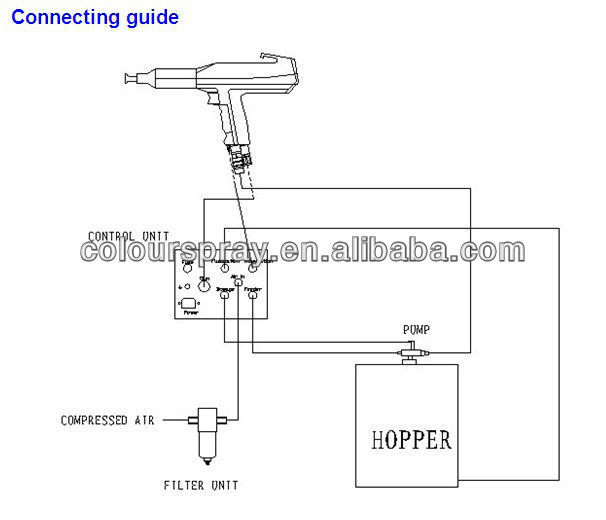

Manual powder coating unit spray booth and curing oven

Double control system,controller has one-touch intelligent operation button good for flat parts, complicated parts,and recoat parts.

Technical data:

Electrical data

Mains input voltage: 220V/110V

Operating frequency:50HZ /60HZ

Powder:50W

Output voltage (to the gun):0-100KV ( adjustable)

Maximum output current (to the gun): 180UA(max)

Protection type:IP54

Approvals:CE Certification

Pneumatical data

Input pressure: min. 6 bar(87PSI)/max. 10 bar(145PSI)

Recommended input pressure: 7 bar(101.5PSI)

Max. water vapor content of the compressed

air 1.3 g/m³

Max. oil vapor content of the compressed air 0.1 mg/m³

Spray Booth

The powder booth fans draw air through filters and releases it through the top of the booth. It keeps your shop nice and clean,minimizing powder dust.

Benefits of our powder booth

- Operator Safety

- Environmental compliance

- Production capacity and operational efficiency

- Color changeover

- longer lasting, more durable, quieter

include fans, motors, nut and bolt fasteners, filters, detailed drawings and instructions, all included in one single shipment.

Data:

One door

Size: W2280mm D1580mm H3000mm / W2380mm D1580mm H3000mm (could make as you want)

Body material: δ=1.5mm galvanized plate

Pulse valves and solenoids

Air velocity 0.6m/s

Recycling fan1/set 4-72-3.6A 3.6 KW

Fliter number 5pcs/set Flither

sizeφ325×900 fast-loading

light: 220v 36w 2 pcs

Voltage is 380V /50HZ (could make as you want)

Curing Oven

- Structure:consist of Body,insulation, cover, heater. use electric to create the energy ,through the circulating fan ,make the temperature in the oven to rise uniformly. Then make the temperature of workpiece to rise.

built-in track to roll your powder coating racks into the ovens could be ordered together as you required.it is free.

Specification

Model | COLO-O |

Overall dimensions | 1000 width x 1000 height x 1500 depth (could make as you want) |

Power supply | electric |

Voltage | 380v |

Frequency | 50-60Hz |

Door type | single |

Warm-up time | 15 min. (180-220° C) |

Homogeneity | < ± 3°C if 185°C |

Temperature stability | < ± 1°C |

Temperature max. | 230° C |

Transport | Top |

Air circulation | Forced |

| |

| |

Warranty | 12 months |

During operation overspray powder accumulates on the cartridge filters. As the cartridge filters load, airflow decreases and the negative pressure rises within the air handler. A timer activates a system of air purging valves that clear the cartridge filters of the accumulated powder to ensure maximum flitter life.

COLO are specialized in complete electrostatic powder coating line, paint coating plants ,curing and drying ovens,

cartridge type and cyclone recovery systems, spray booth, conveyor systems, Also we are supplier of powder coating,

powder filters, powder coating machine,powder coating equipment,powder coatting gun,Reciprocator, painting guns, pumps and their equipments.

- Tel

- *Title

- *Content

- Tel

- *Title

- *Content